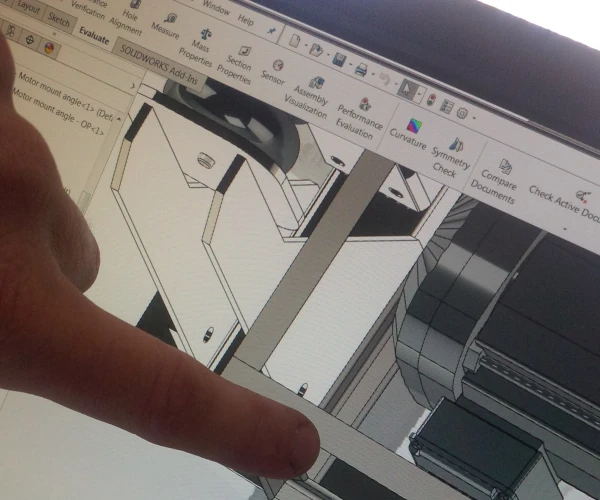

Precision Machining.

Engineering Mindset.

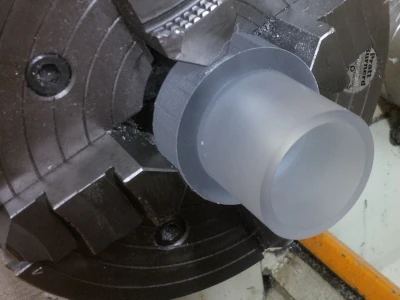

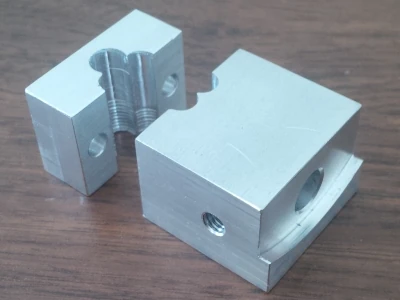

Advanced 2-axis turning, 3-axis milling, and surface grinding. We don't just cut metal; our engineer-led team interprets your design intent for perfect execution.